Management of returns

Returns management redefined

The processing of returns has always been a part of everyday business in press wholesale. The expense for the manual processing (counting, sorting, collecting, resource separation, disposal, etc.) is high. Therefore, the wholesaler must process the returns with a streamlined process and naturally requires inexpensive systems.

The rapidly increasing internet trade has significantly increased the scope of returns processing. The trader’s profits are not to be found in the settling of returns. This process is a ‘necessary evil’ and likewise requires systems with an attractive price-performance ratio.

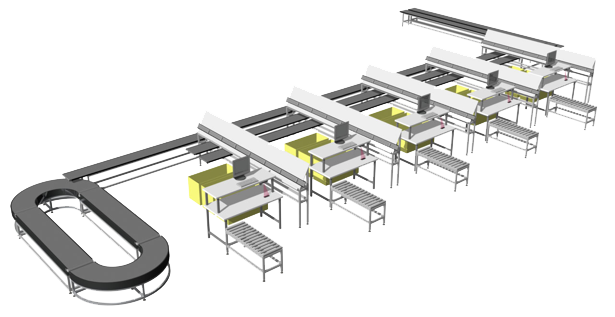

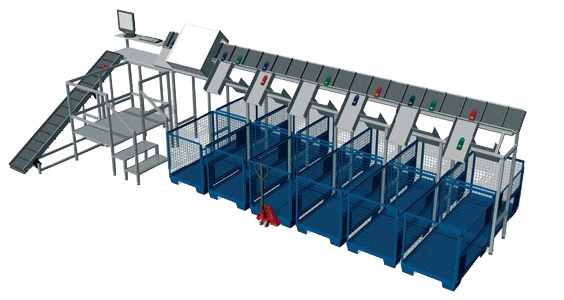

In the last 18 years AutoMatic has developed a family of returns management products specially for the cost-effective settling and processing of returns, and these are in use throughout Europe. In particular the various different products (dimensions, shapes, characteristics, etc.) have resulted in different transport and sorting processes. Also the quantities to be processed and the processing procedures have influenced the design of the respective systems.

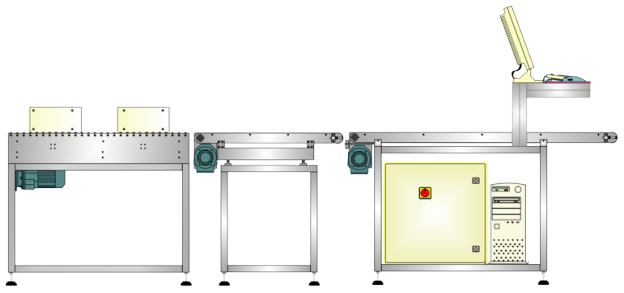

The returns management family comprises a total of 6 systems, which can be employed independently or in combinations. The range stretches from manual processing stations through to fully automatic systems where the goods need only be fed into the machine.

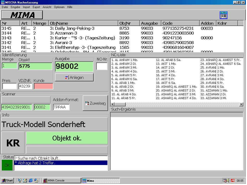

Virtual returns can also be supported by camera recording. Each object is visually recorded during processing and then saved for the verification documentation. The current camera and computer technology makes this possible for very affordable costs. This creates trust and enables the verification of the processing procedure.

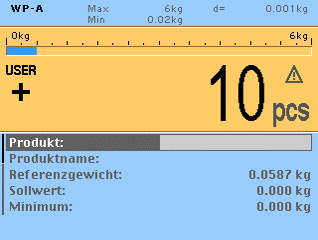

Even before smartphones were introduced to the market, we had all become used to the operation of touch screens, but have also been won over by the significant advantages in operation and display. There are touch screen versions of all members of the returns management system family available. AutoMatic also offers versions for tablet computer for the highest degree of mobility and for changing usage locations, whereby the communication with the sensors, actuators and higher-level computer systems is implemented via WLAN.

In particular where there are manual activities with repetitive sequences of movement, personnel often complain of physical stress and health impairing effects such as shoulder tension, muscular tension etc. through to health-related days of absence. AutoMatic have tasked themselves with the avoidance of these costly and demotivating influences. All return management systems from AutoMatic are ergonomically optimised and enable the processing in many cases in a seated position and/or in relaxed position.