LEICA

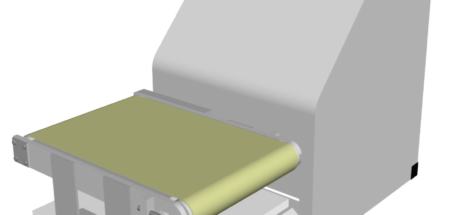

The LEICA weigh checking system is specialised for integration into automated quality and manufacturing processes.

Typical applications

- Individual weight checking of small parts made from plastic or metal, for example

- Completeness checking for products already packed in cartons, boxes or bags

- Testing and checking of article sets

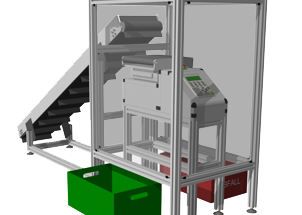

The LEICA system can be integrated into the manufacturing and quality assurance processes in order to statically weigh the products fed to the weighing belt by means of

- Chutes

- Inclined conveyors

- Feed belts or

- Handling robots

enabling them to be checked against their respective, saved target weigh and have their tolerances checked. GOOD weights are automatically fed to the left by the weighing belt, BAD weights to the right. The running direction can be changed in the set-up.

Highlights

- Simplest operation through logical user guidance

- Easy process integration via variety of interfaces

- Illuminated alpha-numeric 4-line display

- Right/left running for automatic sorting by GOOD/BAD

- Product feeding manual or external for flexible handling

- Precision weighing technology for determining the smallest of errors in weight

- Rapid weight detection for high through-put rate

- Modular construction for flexible adaptation and integration