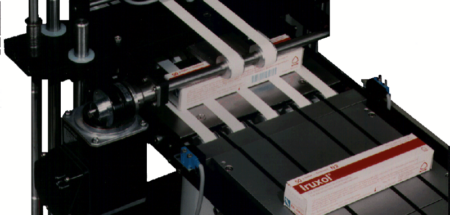

The dynamic check weigher AM2 is optimised for the 100% checking of small products (collapsible boxes, small bottles, cans, small bags). Alongside the weight checking the modular design of the system enables the integration of additional sensors for the enhancement of the product inspection.

Product description

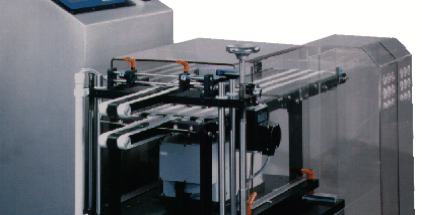

With the dynamic check weigher AM2 you have made the right choice for the checking of products up to 500g. For the transportation of very small collapsible boxes a toothed transport system with fine link chains is employed in order to avoid an angled pulling of the products when transferring between the transport sections. With small glasses, small bottles or cans with high centres of gravity, adapted screws are used in order to guarantee transportation without toppling. With the option of an over-runner and under-runner, your products can be directly accepted from the upstream packaging machine.

As with all AutoMatic checking systems the production data determined can be transferred via the network or Fieldbus for your documentation or archiving. Logging can be implemented either directly, locally, or manually via the network or even automatically. Of course everything is also available as a calibratable version.

Typical applications

- Checking and controlling of filling machines

- Simplest operation with colour display and softkeys

- Comprehensive software library for a great variety of different applications

- Precision weighing technology for determining the smallest of errors in weight

- Calibratable

- Process integration via variety of interfaces

- Logging and/or archiving of the process data via the network

- Integrated functions specially for the pharmaceuticals and cosmetics industries

Highlights

- Completeness checking for small products up to 500g

- Monitoring and checking of filling and packaging machines