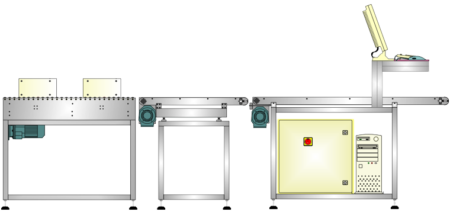

Product description

The MISCHA system is specially tailored to the requirements of modern returns processing. Efficiency, rapidity, ergonomics and intuitive operation as well as a seamless integration into the flow of existing processes are the qualitative and quantitative yardsticks. Not only with objects up to 500 x 600mm, with the advent of stackable products, with an average stack height of more than 2 objects per article and with a requirement for more than 5 sorting compartments/boxes, is MISCHA the right choice. The 100 percent checking of all processed objects builds trust and provides 100% customer satisfaction.

The highlight of the MISCHA system is undoubtedly the stack processing (simultaneous acquisition of identical objects). In the classical returns systems, each object must be identified individually with a scanner. The process is undertaken equally for differing and for identical objects. The MISCHA system offers an innovative contribution to increase efficiency here. Identical objects are recorded and correctly counted in a single processing pass as a complete stack. Scales integrated into the system record the total weight of the stack and calculate the correct number of returns with the known individual weights.

Overview and technical data

- Automatic VR-goods and stock goods sorting in a single process step

- Stock goods sorting fully automatic through separate ejection

- No pre-sorting of objects necessary

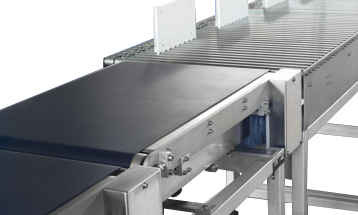

- Stack processing through integrated weighing technology or conventional individual placement

- Processing of plus-products – “gimmicks” and uncoded products

- Weight checking for reliable detection of missing parts (not only with plus-products)

- Document-related acquisition and customer-related counting

- Reference quantity checking with automatic comparison of the object checking

- Automatic customer change with available customer codes

- Output-related counting and ejection of objects through Copy-Count-Compartment function

- Simultaneous identification of all current barcodes

- Rapid acquisition function for non-coded or non-acquired objects

- Match-code search function (name, number, price)

- Real-time statistics functions

- Internal logic for early and/or late returns

- Manual corrective bookings possible

- Automatic generation of German or CCG codes

- Support for daily returns collection

- Correction of barcodes possible

- Remote maintenance

- Independent database for offline operation

- Selectable acoustic signals for definable events

- History window for acquired objects

- Dynamic customer-related totals display

- Object quantity checking

- Automatic generation of a list of manually modified object data

- Network server as cluster in a higher-level network

- Multi-directional scanner for arbitrary placement of objects

- Manual marking of special objects for separate acquisition

- Further transportation technology

- Weighing of the individual collecting containers via floor scales

- Management of individual and tare weights

- Workstation for manual re-working of special products

- Ejection of unrecognised or not-found objects

- UPS to protect the system in the event of a mains power failure

- Guidance in application-specific technical and design areas

- Project planning and project support

- Installation and commissioning – worldwide