Sorting

Sorting in all directions

When sorting and/or distributing products, your high quality articles must not incur even the tiniest of damage. Whilst taking into account the product characteristics, the weights and the requirements of your process (sorting direction, spatial restrictions, etc.), AutoMatic offers an optimised sorting system that will handle your products gently. The sorting of thin products (paper sheets) to the same sorting position to the right (e.g. DIN A4) and to the left (e.g. DIN A5) has been part of the standard fare at AutoMatic for many years, just as the individual sorting of not-yet-closed bottles or cans filled with liquids has been.

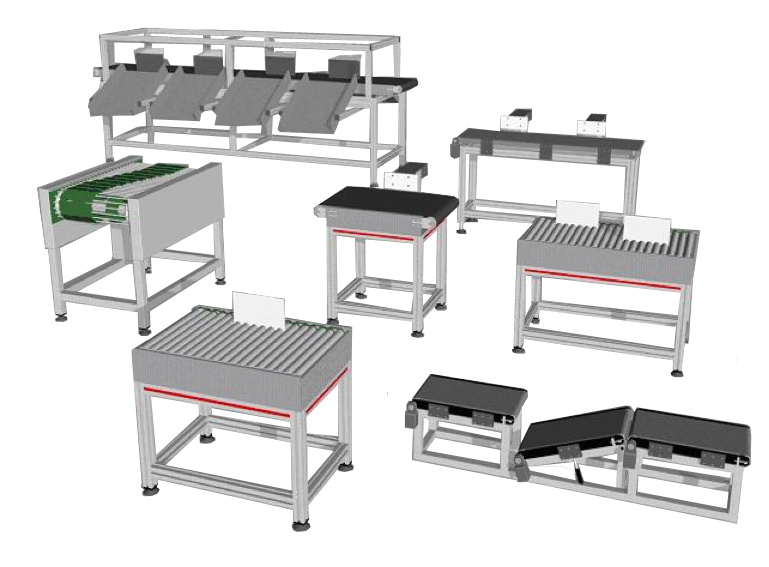

For the sorting of a great variety of products we can supply:

- Blower nozzles

- Pushers

- Switches

- Flaps

- Flap belts

- Multiple sorting stations

- Corner turning stations

- Push sorters

- Line splitters

- Gravitation sorters

- Individual solutions

Blower nozzles

Objects from just a few grams to weights of 250g can be sorted with our blower nozzles. The sorting performance can be up to 400 units/min. and more, depending on the product.

Pushers

Objects from just a few grams to weights of 50kg can be sorted with our pushers. The sorting performance can be up to 200 units/min., depending on the product.

Objects from just a few grams to weights of 50kg can be sorted with our pushers. The sorting performance can be up to 200 units/min., depending on the product.

Switches

Our product switches deflect the product to be sorted out at an angle to the running direction.

Our product switches deflect the product to be sorted out at an angle to the running direction.

Objects from just a few grams to weights of a few kg can be sorted with our switches. The sorting performance can be up to 150 units/min., depending on the product.

Flaps

Our sorting flaps normally comprise driven belt sections which divert the products downwards. The sorted products are collected either by additional transport technology or by sorting containers.

Objects from just a few grams to weights of a few kg can be sorted with our sorting flaps. The sorting performance can be up to 80 units/min., depending on the product.

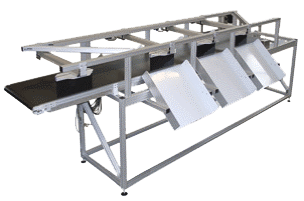

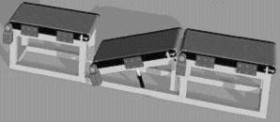

Flap belts

Our sorting flaps comprise a sequence of multiple sorting flaps on a common sub-frame and normally comprise driven belt sections which divert the products downwards. The sorted products are collected either by additional transport technology or by sorting containers.

Our sorting flaps comprise a sequence of multiple sorting flaps on a common sub-frame and normally comprise driven belt sections which divert the products downwards. The sorted products are collected either by additional transport technology or by sorting containers.

Objects from just a few grams to weights of a few kg can be sorted with our flap belts. The sorting performance can be up to 80 units/min. per sorting flap, depending on the product.

Multiple sorting stations

The SSL-001 multiple sorting station was developed for quick sorting as a space-saving solution for medium sized products (e.g. newspapers, magazines, small cartons, and similar). In doing so the products are diverted by pushers with lifting and pushing movements to the same position in both directions, perpendicular to the transportation direction. The sorting performance can be up to 80 units/min. per sorting station, depending on the product.

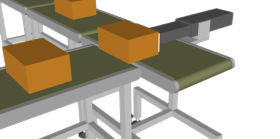

Corner turning stations

Depending on product characteristics, our corner turning stations are realised with pushers, driven belts or chain belts. Corner turning stations are used where there are spatial restrictions or with the so-called zero-error process. In doing so only the products designated as GOOD by the upstream classification system are passed on to the next processing station by the corner turning station. The possibility of passing on an unchecked or faulty product is excluded with the active corner turning station.

Depending on product characteristics, our corner turning stations are realised with pushers, driven belts or chain belts. Corner turning stations are used where there are spatial restrictions or with the so-called zero-error process. In doing so only the products designated as GOOD by the upstream classification system are passed on to the next processing station by the corner turning station. The possibility of passing on an unchecked or faulty product is excluded with the active corner turning station.

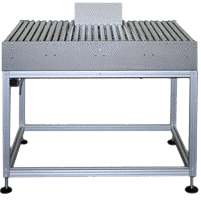

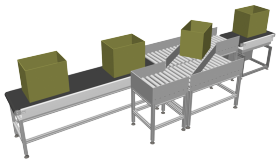

Push sorters

Small items (sheets of paper 10cm x 10cm) through to weights of up to 30kg can be sorted whilst handling the products carefully with a push sorter based on a roller conveyor driven with round belts. The construction enables a precise arrangement of the sorted products at right angles to the running direction. Variable speeds up to 1.0m/s and sorting frequencies of up to 4,800 unit/hour can be achieved with the pneumatic sorting and the special and very quiet, smooth running bearings of the transport rollers. The complete unit is constructed from low-wear elements and is thus almost maintenance-free. The push sorters can be expanded at any time by cascading. The transportation height can be arbitrarily adapted to suit the specific conditions, from 400mm.

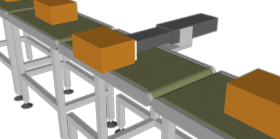

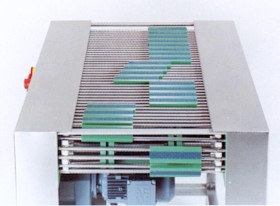

Line splitters

With our line splitters, individual push plates are deflected to predefined tracks. The products on the deflected push plates are sorted to two or more tracks with little lateral acceleration. The sorted products are collected by additional transport technology downstream of the line splitter.

With our line splitters, individual push plates are deflected to predefined tracks. The products on the deflected push plates are sorted to two or more tracks with little lateral acceleration. The sorted products are collected by additional transport technology downstream of the line splitter.

Objects from just a few grams to weights of a few kg can be sorted with our line splitters. The sorting performance can be up to 300 units/min., depending on the product.

Gravitation sorters

A great variety of products can be separated on a common sorting section with our gravitation sorters. The products are transported past the sorting station on an inclined belt in any sequence and with arbitrary spacing. The products to be sorted are diverted from the conveyor belt with a pusher adapted to suit the product range, and fed into a receiving container or a further transportation system by means of the products’ own weight and guide rails.

The following products are amongst those that can be sorted with a gravitational sorter:

- Newspapers and magazines

- Videos, CD, DVD etc

- Bottles for nail varnish or similar

- Collapsible boxes and small cartons

- Tubes and plastic bottles

Various other types of product and packaging are possible. Exceptions to this are open cans or bottles with contents, for example.

A sorting performance of over 10,000 units per hour can be achieved, depending on the product and application.

Individual solutions

We can develop the optimum solution for your process for special requirements and applications in the area of weighing, sorting, classification etc. where standard sorting processes cannot be used.