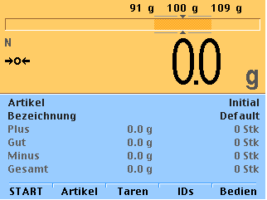

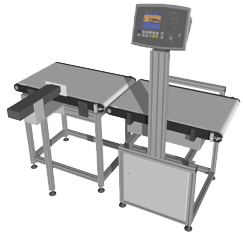

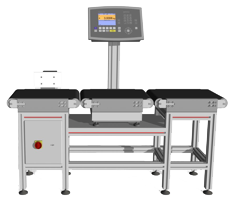

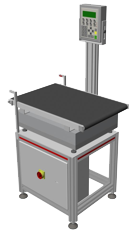

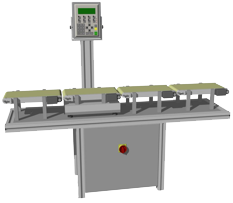

Dynamic Check Weighers

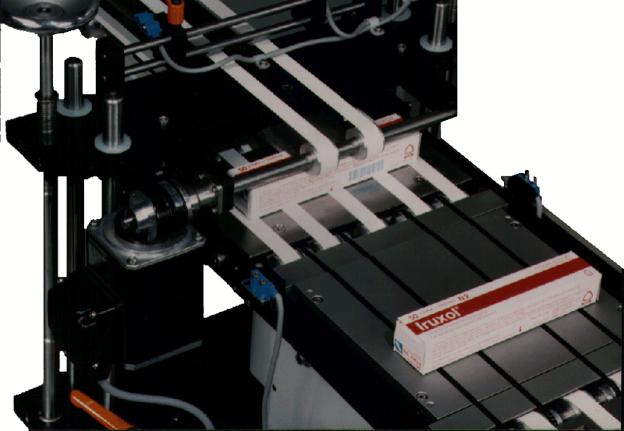

The dynamic check weighers from AutoMatic are used wherever the weight, and potentially other product characteristics, are of critical importance for quality assurance and in automatic and continuous manufacturing processes that require a 100% check of the products. In doing so, over-filling and under-filling can be avoided, unnecessary material losses saved, recall actions avoided and thus your profits maximised, whilst simultaneously improving your market image. Small products in the range of a few grams through to packaging in the form of boxes or bags in the range of several tens of kg can be securely checked and sorted with the AutoMatic check

weighers. Integration into the process control via digital signals or conventional Fieldbus systems and networks is likewise possible, as is the checking and regulation of filling machines and also the use in applications that are subject to mandatory calibration. Multi-lane systems with a central controller are used for high through-put rates and to achieve high levels of accuracy.

weighers. Integration into the process control via digital signals or conventional Fieldbus systems and networks is likewise possible, as is the checking and regulation of filling machines and also the use in applications that are subject to mandatory calibration. Multi-lane systems with a central controller are used for high through-put rates and to achieve high levels of accuracy.