Product description

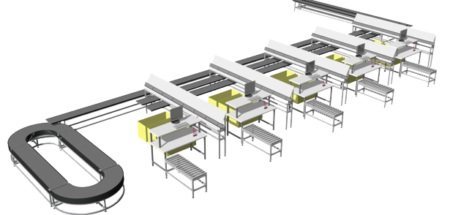

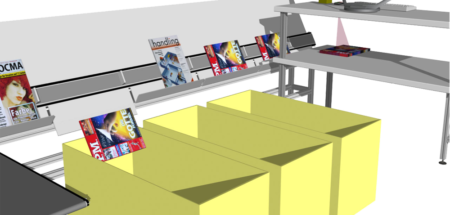

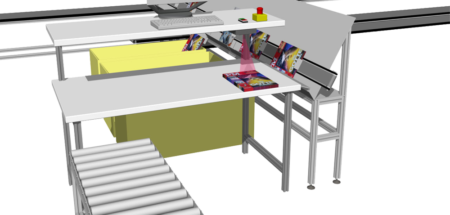

“Just push your work off your desk and let someone else do it” – this is how SARA works. You push (and why not whilst sitting) the objects off the table individually, into the feed section. SARA takes the object automatically and carries out the next functions (counting, sorting, totalling, etc.). You need not concern yourself with it after this, not even with the collection of special objects. Only the information regarding which customer/debtor is currently being dealt with needs

to passed on to SARA. And this is most often also done without manual input, automatically via the scanner. In particular with products that cannot be stacked or with the advent of objects with low article stack height, the 100% checking of the returns can be guaranteed with SARA using the one-by-one method. Space-saving and cost-effective as a stand-alone system or to be integrated into a central, multi-lane sorting belt system, SARA is the right choice.

Overview and technical data

- Automatic VR-goods and stock goods sorting in a single process step

- Stock goods sorting fully automatic through separate ejection

- No pre-sorting of objects necessary

- Processing of plus-products – “gimmicks” and uncoded products

- Document-related acquisition and customer-related counting

- Reference quantity checking with automatic comparison of the object checking

- Automatic customer change with available customer codes

- Output-related counting and ejection of objects through Copy-Count-Compartment function

- Simultaneous identification of all current barcodes

- Rapid acquisition function for non-coded or non-acquired objects

- Match-code search function (name, number, price)

- Real-time statistics functions

- Internal logic for early and/or late returns

- Manual corrective bookings possible

- Automatic generation of German or CCG codes

- Support for daily returns collection

- Correction of barcodes possible

- Remote maintenance

- Independent database for offline operation

- Selectable acoustic signals for definable events

- History window for acquired objects

- Dynamic customer-related totals display

- Object quantity checking

- Automatic generation of a list of manually modified object data

- Network server as cluster in a higher-level network

- Manual marking of special objects for separate acquisition

- Further transportation technology

- Weighing of the individual collecting containers via floor scales

- Workstation for manual re-working of special products

- Ejection of unrecognised or not-found objects

- UPS to protect the system in the event of a mains power failure

- Guidance in application-specific technical and design areas

- Project planning and project support

- Installation and commissioning – worldwide