Product description

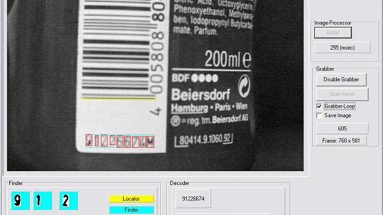

If additional product properties are to be investigated and taken into account in the classification, then camera technology with OCR/ICR technologies can be used in order to record the “use by” date or batch numbers for example. With large processing quantities the articles being processed are automatically sorted into pallet cages for example, by the system. Stipulations regarding the content, or potentially the individual and total weights, as well as other stipulations in the form of delivery notes / freight papers for the large containers to be filled, should be created and provided for deliveries or further processing. To do so, a sorting box management

system is employed, optimised for your process. This compressive and versatile case is realised with the LISA system. With the system flexibility, the application-related software library and the modularity we are able to assemble a system that fulfils your process with your requirements and which records all objects in accordance with your various stipulations and which sorts and separates them into an arbitrary number of compartments, boxes, etc. Special products (defective, damaged, incomplete, etc.) can be handled separately through the configurable behaviour of the LISA system.

Overview and technical data

- Processing of bottles, tubes, small bottles and collapsible boxes

- Arbitrary number of sorting compartments or boxes

- Communication with in-house network

- Connection to SAP system or other merchandise management systems

- Simplest operation with just one person

- Highest through-put rate of up to 60 objects per minute

- Low spatial and energy requirements

- Robust technology, low maintenance effort, low noise level

- High degree of adaptability to customer-specific conditions through flexible import and export functions

- Online modem connection for maintenance, updates, analyses and help facility for the user

- Short amortisation time

- Expandability through to fully integrated automation concept

- Determination of sales and turnover figures

- Further transportation technology

- Weighing of the individual collecting containers via floor scales

- Management of individual and tare weights

- Workstation for manual re-working of special products

- Guidance in application-specific technical and design areas

- Project planning and project support

- Installation and commissioning – worldwide