Product description

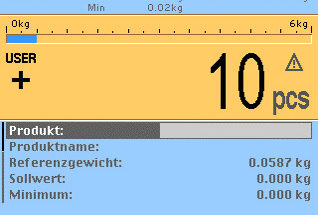

The use of the EVA system provides just the right assistance here. EVA determines the number of units of these types of products with a check weigher, quickly, precisely and without errors. In addition, the products are fed into a specially designed catchment bowl and after the measurement/counting process are automatically discharged onto a conveyor belt or into a container. With EVA, the complete counting

process is completed within max. 2 seconds, thus saving costly working time. As a stand-alone system, EVA is equipped with a screen and a scanner to identify the articles and the customer/debtor. As an ADD-ON to the returns management family of systems, EVA communicates directly with the system partner and the data is displayed on the partner’s screen.

Overview and technical data

- No pre-sorting of objects necessary

- Document-related acquisition and customer-related counting

- Reference quantity checking with automatic comparison of the object checking

- Automatic customer change with available customer codes

- Simultaneous identification of all current barcodes

- Match-code search function (name, number, price)

- Real-time statistics functions

- Internal logic for early and/or late returns

- Manual corrective bookings possible

- Automatic generation of German or CCG codes

- Support for daily returns collection

- Correction of barcodes possible

- Remote maintenance

- Independent database for offline operation

- Selectable acoustic signals for definable events

- History window for acquired objects

- Dynamic customer-related totals display

- Object quantity checking

- Automatic generation of a list of manually modified object data

- Further transportation technology

- UPS to protect the system in the event of a mains power failure

- Guidance in application-specific technical and design areas

- Project planning and project support

- Installation and commissioning – worldwide